Advanced Conductor Technologies LLC and the Applied Superconductivity Center within Florida State University’s National High Magnetic Field Laboratory have successfully demonstrated the world’s first high-current, high-field insert magnet wound from high-temperature superconducting cables, operating in tandem with a low-temperature superconducting outsert magnet. The successful test has a major impact on the development of future particle accelerator magnets and compact fusion machines.

The insert magnet development was part of a Small Business Innovative Research (SBIR) grant from the United States Department of Energy, Office of High Energy Physics that encourages small businesses to partner with academia to develop new technology. The grant aimed to develop ACT’s Conductor on Round Core (CORC®) magnet cables for use in the next generation of particle accelerators that generate magnetic fields exceeding 20 T. As part of a particle accelerator, such magnets will allow particles to collide at even higher energies than those resulting in the discovery of the Higgs boson at the Large Hadron Collider in 2013.

“Advanced Conductor Technologies has developed this high-field magnet conductor over the past 7 years. We are convinced that CORC® cables are able to achieve the required performance and withstand the high stresses that occur during operation at high magnetic fields. Moving the technology from a short sample level into an actual long-length high-field magnet conductor was a significant challenge. I’m extremely pleased that we were able to achieve this and demonstrate the maturity of CORC® magnet cables with the high-field insert magnet test”, said ACT’s founder Danko van der Laan.

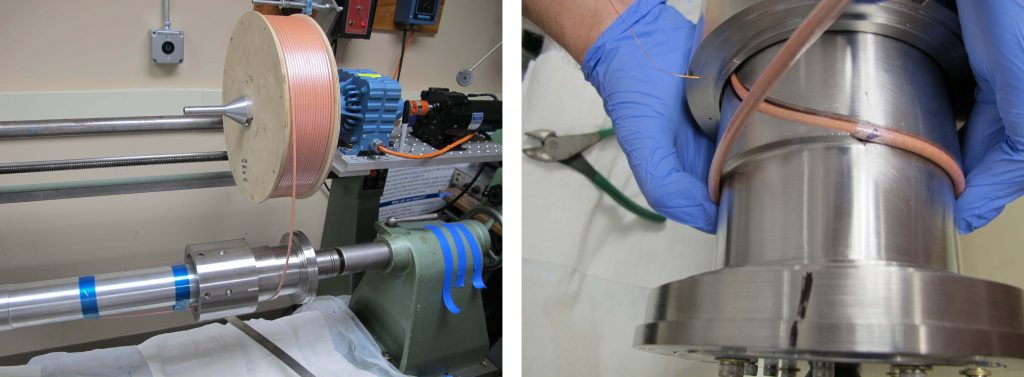

The next generation of particle accelerators will require high-temperature superconducting cables to operate at very high currents of several kilo-Amperes. The cables need to be flexible to allow winding into high-field magnets and need to withstand the very high forces that occur during operation. The 4.5 mm thick CORC® magnet cable was wound from 28 REBCO tapes grown on a high-strength 30 µm thin substrate specifically developed for the insert magnet.

“I am proud that the Applied Superconductivity Center could achieve this very significant milestone with Advanced Conductor Technologies. The successful test validates the Conductor on Round Core approach toward low-inductance high-field magnets for future accelerators, fusion, and other applications. Much credit goes to Danko van der Laan for his consistent vision”, according to the Director of the Applied Superconductivity Center, Lance Cooley.

The high-temperature superconducting insert magnet was wound from 18 meters of high-current CORC® cable and designed to withstand forces in excess of 250 MPa during operation. The magnet was installed inside the large-bore 14 T low-temperature superconducting magnet at the Applied Superconductivity Center. The test facility was specially expanded for this test to allow operating currents up to 7,200 A, while also providing the magnet protection circuit in case the insert would develop a fault.

Ulf Trociewitz, staff scientist at the ASC and developer of the test bed spoke about the test: “The high current setup and the new 14 T, 160 mm, large bore magnet offers an excellent facility for further HTS cable and magnet R&D work well beyond this particular test, providing an accessible and affordable test bed for HTS magnet development. It all worked very well.”

The two magnets reached a combined central magnetic field of 15.8 T, with the insert magnet operating at a current of 4,400 A, and a current density of over 280 A/mm2. The peak field at the HTS cable was 16.7 T. This was the first demonstration of a high-temperature superconducting insert magnet that operated at several kilo-Amperes in a background magnetic field.

“Current sharing between the superconducting tapes in the CORC® cable allowed the magnet to operate up into the flux-flow regime. This has not generally been possible in high-field magnets wound from single REBCO tapes, where unpredictable quenches often lead to conductor burnout,” said NHMFL Chief Materials Scientist David Larbalestier. Here the CORC® cable insert magnet operated well above its so-called critical current, operating stably in its dissipative state without causing a thermal runaway, or quench.

In addition to Trociewitz, Larbalestier, Cooley and Van der Laan, other scientists working on the project include Jeremy Weiss of Advanced Conductor Technologies; Dima Abraimov, Ashleigh Francis, James Gillman, Daniel Davis, Youngjae Kim, Van Griffin, George Miller and Huub Weijers of the NHMFL; and Xiaorong Wang of the Lawrence Berkeley National Laboratory.